Hand Made Construction of our Acoustic & Classical Guitars Means

Incredible Sound Quality at Unbeatable Prices

All guitars with the Goyette name are carefully and meticulously hand-crafted overseas in the shops of expert luthiers with many years of experience building high-quality student and concert-level guitars. Strict humidity and temperature control is maintained at all times. These guitars compare favorably with more expensive guitars made by individual luthiers. Instead of a single luthier constructing the guitar, from start to finish, more than one luthier may be involved in the process of building a single Goyette guitar, under the supervision of a single “master luthier.”

The resulting labor cost savings and production efficiencies result in a lower-priced guitar, but identical in quality to guitars made by individual luthiers, even those with famous, well-known names, some of which cost thousands of dollars more. The student, models, although made with less expensive materials, all have solid wood soundboards and are constructed with the same exacting standards as the more expensive concert models. Cosmetically, many of them are identical in finish and appearance to their more expensive counterparts.

|

|

Attaching the Back to the Sides |

Roughly Finished Tops Waiting for the Next Step. |

|

|

Shaping Guitar Top Fan Braces. Various types of fan |

Hand Shaping the Heel. |

|

|

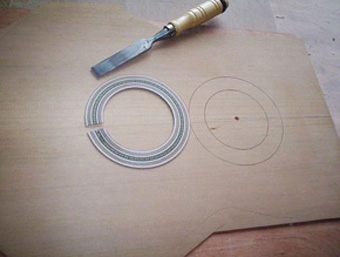

Installing a Custom Rosette. |

Partially Finished Guitars Waiting for Decoration and Inlays. |

|

|

Airing the Tops Out and Giving them Time to |

Installing Fretwire by Hand. |

|

|

Binding the Top to the Sides. |

Hand Shaping the Neck. |

|

|

Hand Sanding the Neck. |

Hand Polishing the Frets and Fretboard. |

|

|

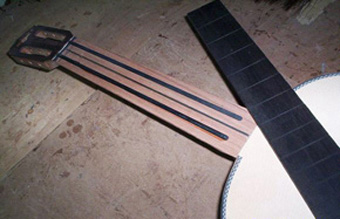

Carbon Fibers Inserted into the Neck Help Carry the Sound.

|

Using Bamboo Strips to Assist the Bonding Process.

|

Preparing the Top for Attaching the Bridge. |

Hand Polishing the Braces for Better Sound. |

|

|

Bonding the Bridge to the Top |

Preparing to Install the Rosette. |